what is the percentage of carbon in medium carbon steel Heat treating steel time vs temperature and case harden thickness

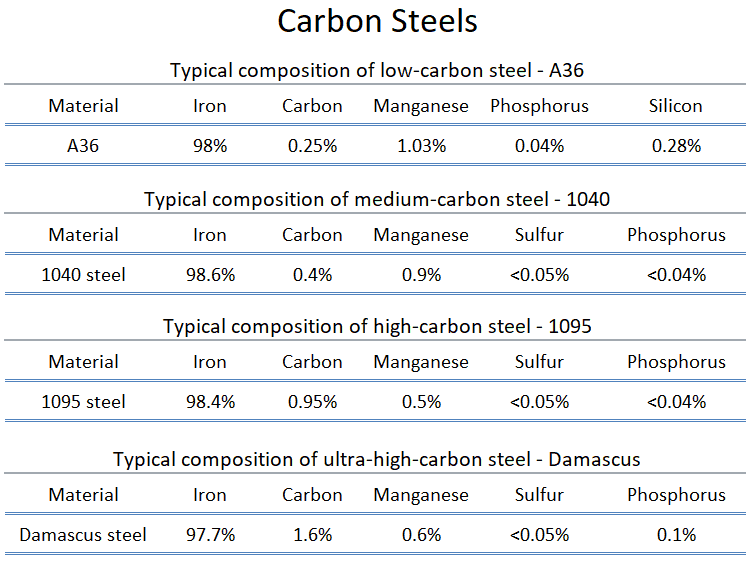

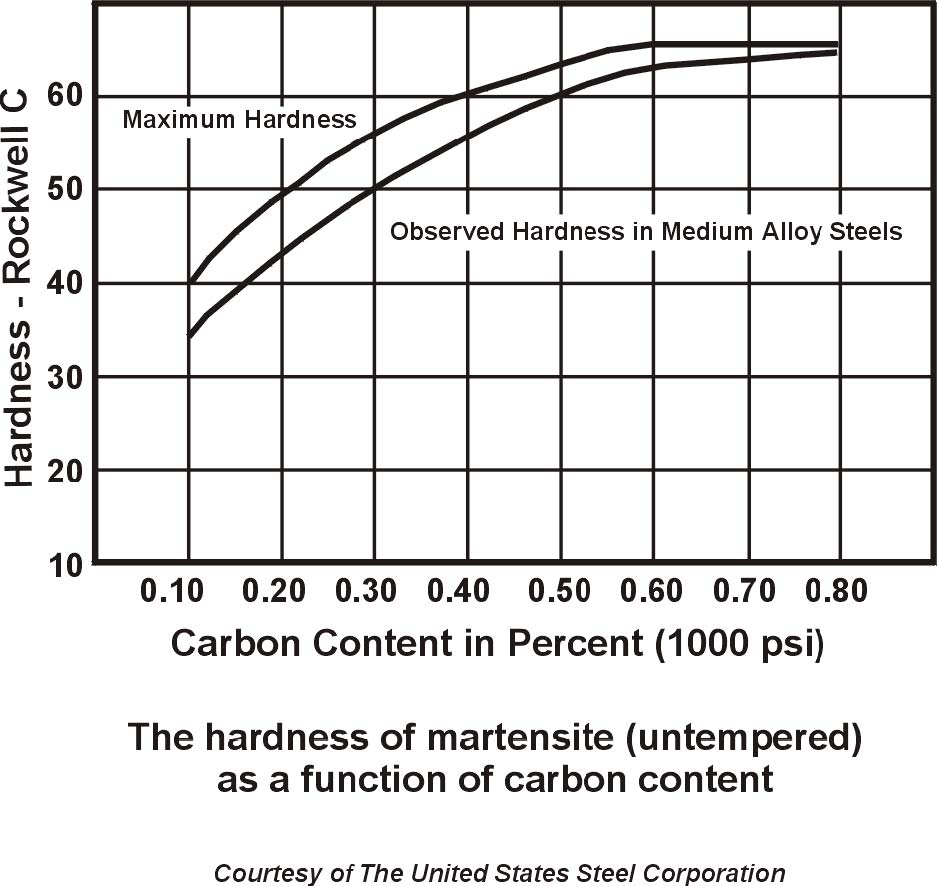

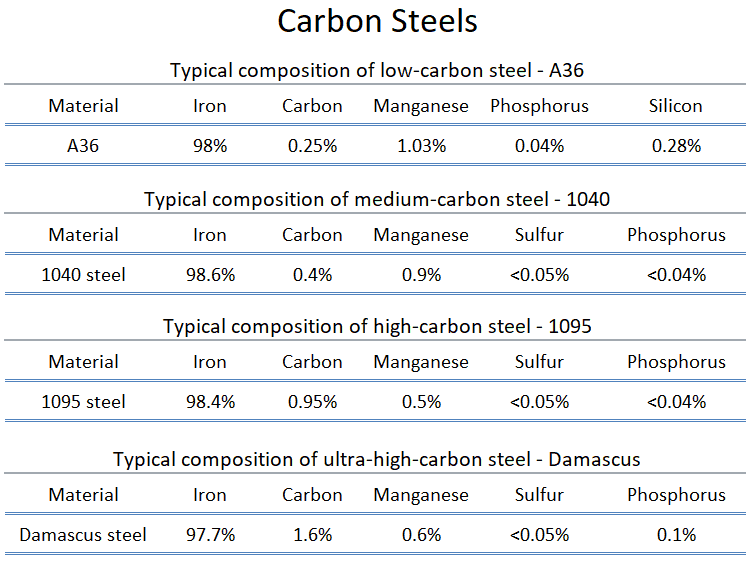

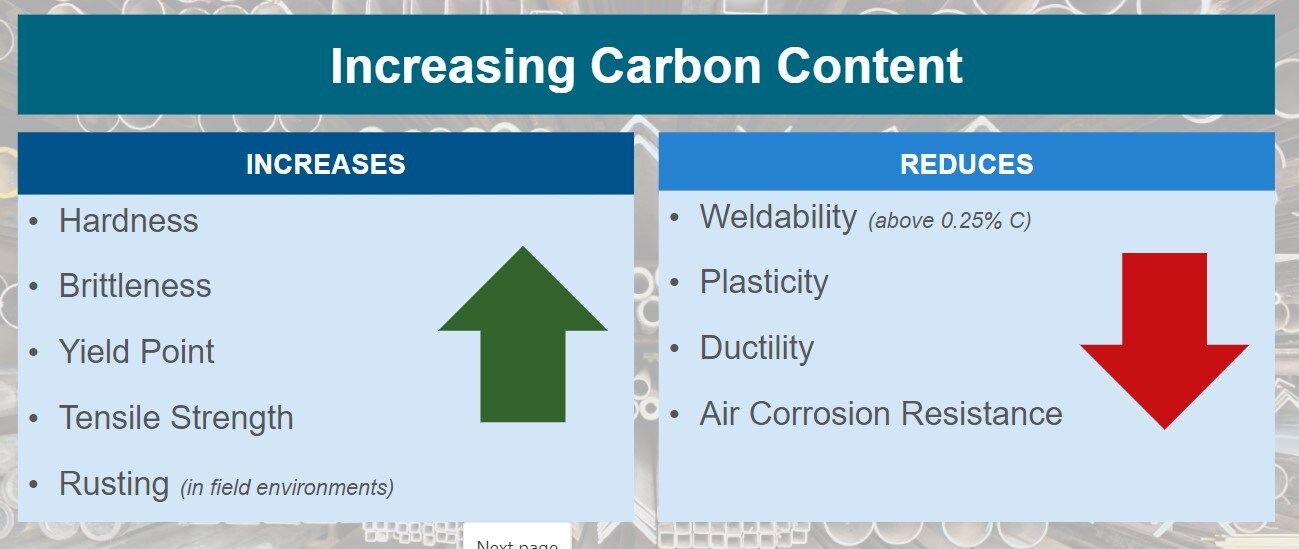

When it comes to steel, there are various types that differ in their carbon content. The percentage of carbon in steel has a significant impact on its properties and characteristics. In this post, we will explore the differences between mild steel, medium carbon steel, and high carbon steel.

Mild Steel:

Mild steel, also known as low carbon steel, is the most commonly used form of steel due to its low cost and versatility. It typically contains a carbon percentage of 0.05-0.25%. This amount of carbon allows mild steel to be easily machined, formed, and welded.

Mild steel, also known as low carbon steel, is the most commonly used form of steel due to its low cost and versatility. It typically contains a carbon percentage of 0.05-0.25%. This amount of carbon allows mild steel to be easily machined, formed, and welded.

One of the main advantages of mild steel is its high ductility, which enables it to be stretched without breaking. It is also relatively soft and malleable, making it ideal for applications such as construction, automotive manufacturing, and furniture production.

However, mild steel has lower strength compared to medium and high carbon steels. It is not suitable for applications that require high hardness or wear resistance. Additionally, it tends to corrode more easily when exposed to moisture and other environmental elements.

Medium Carbon Steel:

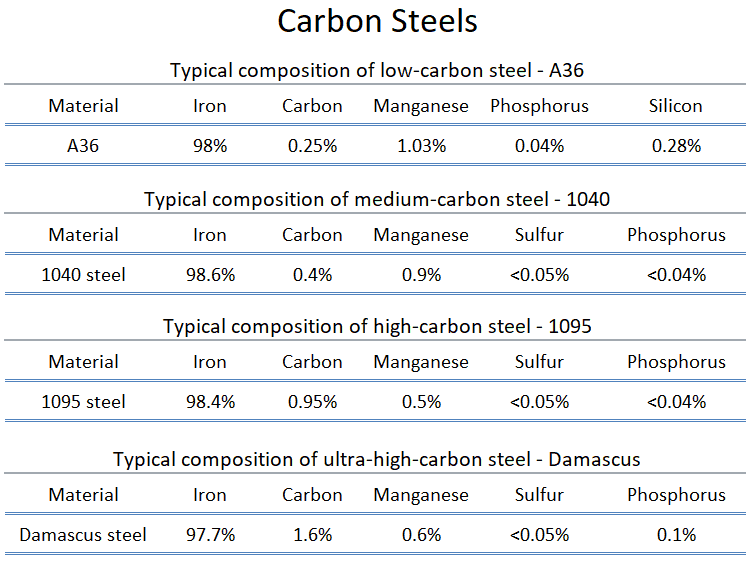

Medium carbon steel contains a higher percentage of carbon, typically ranging from 0.25% to 0.60%. This increased carbon content enhances its strength and hardness compared to mild steel. Medium carbon steel strikes a balance between ductility and strength, making it suitable for a wide range of applications.

Medium carbon steel contains a higher percentage of carbon, typically ranging from 0.25% to 0.60%. This increased carbon content enhances its strength and hardness compared to mild steel. Medium carbon steel strikes a balance between ductility and strength, making it suitable for a wide range of applications.

Due to its improved strength, medium carbon steel is commonly used in the manufacturing of gears, axles, crankshafts, and railway wheels. It can also be heat-treated to further enhance its hardness and wear resistance.

However, medium carbon steel is less malleable than mild steel and may be more challenging to weld. It is also more prone to corrosion, especially in environments with high humidity or exposure to chemicals.

High Carbon Steel:

High carbon steel contains the highest percentage of carbon among the three types, typically ranging from 0.60% to 1.0%. This results in significantly increased hardness, strength, and wear resistance. High carbon steel is primarily used in applications that require durability and the ability to withstand heavy loads.

High carbon steel contains the highest percentage of carbon among the three types, typically ranging from 0.60% to 1.0%. This results in significantly increased hardness, strength, and wear resistance. High carbon steel is primarily used in applications that require durability and the ability to withstand heavy loads.

Some common uses of high carbon steel include cutting tools like knives, chisels, and saw blades, as well as springs, piano wires, and bicycle frames. Its exceptional hardness also makes it suitable for the production of ball bearings and other high-wear components.

However, high carbon steel has lower ductility and may be more brittle compared to mild and medium carbon steels. It is less suitable for applications that require high impact resistance. Additionally, high carbon steel is more susceptible to corrosion, and proper maintenance is necessary to prevent rusting.

In conclusion, the percentage of carbon in steel significantly affects its properties and applications. While mild steel offers affordability and versatility, medium and high carbon steels provide increased strength and durability. Careful consideration of the desired qualities and application requirements is essential when choosing the most suitable type of steel.

If you are searching about The approximate percentage of carbon in low alloy steel | Download Table you’ve came to the right place. We have 5 Images about The approximate percentage of carbon in low alloy steel | Download Table like The approximate percentage of carbon in low alloy steel | Download Table, Mild Steel vs Medium vs High-carbon Steel - Comparison - Pros and Cons and also How Carbon Affects the Quality of Steel Weldability and Hardness. Here it is:

The Approximate Percentage Of Carbon In Low Alloy Steel | Download Table

www.researchgate.netpercentage approximate

www.researchgate.netpercentage approximate

Heat Treating Steel Time Vs Temperature And Case Harden Thickness

www.engineersedge.comsteel vs carbon hardness heat case treating thickness time temperature harden

www.engineersedge.comsteel vs carbon hardness heat case treating thickness time temperature harden

[SOLVED] As Percentage Of Carbon Increases In Steel, Its

![[SOLVED] As percentage of carbon increases in steel, its](https://storage.googleapis.com/tb-img/production/20/02/F1_R.Y_Madhu_T.T.P_20.02.20_D1.png) selfstudy365.comMild Steel Vs Medium Vs High-carbon Steel - Comparison - Pros And Cons

selfstudy365.comMild Steel Vs Medium Vs High-carbon Steel - Comparison - Pros And Cons

material-properties.orgsteels properties alloys pros strengths

material-properties.orgsteels properties alloys pros strengths

How Carbon Affects The Quality Of Steel Weldability And Hardness

www.thermofisher.comweldability affects hardness weld metals decay glance

www.thermofisher.comweldability affects hardness weld metals decay glance

Weldability affects hardness weld metals decay glance. Percentage approximate. Mild steel vs medium vs high-carbon steel